What is shielding? What should be considered in shielding?

In everyday life, from the sound systems we use to robotic arm applications, our cables are exposed to electromagnetic fields. This field, known as EMI (Electromagnetic Interference), can distort the signal passing through the cable and even cause system malfunctions. In this article, we will provide basic information about shielding, which is used to prevent these negative effects.

What is Shielding? Shielding is the process of electromagnetically isolating cables, circuits, or devices. The quality of shielding depends on the type of source being shielded and the quality of the shielding elements. Fundamentally, there are two types of shielding: general shielding and individual shielding.

- In individual shielding, one or several cable groups are shielded.

- In general shielding, all groups are shielded together.

Why is Shielding Conductors Important?

- It increases the physical durability of cables.

- It prevents electromagnetic interference (EMI) from distorting the signal in the cable.

- It ensures secure and high-quality cable communication.

- It prevents induced currents on the cable, protecting equipment from damage.

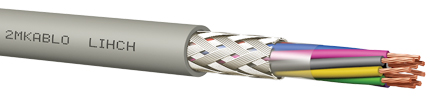

Figure 1: Proper shielding of cables significantly affects transmission quality.

Shielding Methods

Wrapping, braiding, and foiling are the basic coating methods used in shielding. In addition to these, there are various combinations such as braid–foil depending on the application area. Each method has its own advantages and disadvantages.

Shielding can vary in features and types depending on the cable’s field of use, the environmental conditions in which it is applied, and its intended purpose. In this way, a method that will be efficient for each specific application can be selected, thereby improving work quality.

This approach, which also covers the electrical efficiency of the cable, enables higher operational performance.

Figure 2: Cable Shielding Methods – Braided Shielding

- Provides high physical durability

- Offers flexibility

- Covers between 40% and 98% of the cable (which increases shielding quality)

- Can be applied to wires of any diameter

- Suitable for bending movements; preferred in robotic and automation applications

- Has a high cost

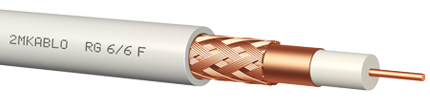

Figure 3: Cable Wrapping with Braided-Type Shield

- Resistant to twisting

- Provides superior flexibility

- Covers approximately 97% of the cable

- Electrical performance is low at high frequencies

Figure 4: Cable Wrapping with Foil Shielding

- Low cost

- Easy to install

- Provides 100% cable coverage

- Has low mechanical strength

Figure 5: Cable with Foil Shield – Braid–Foil Combination

- Although more expensive than other cables, it is a very important shielding method for high-quality performance

- Provides 100% shielding

- Since both braid and foil are used, it offers high mechanical strength

- The conductor used in shielding has low internal resistance

- Has a structure that completely surrounds the cable

Figure 6: Cable with Braid–Foil Combination – Cables Used in Thermal and Geothermal Power Plants

Today, power generation plants hold great importance both in our country and worldwide. The energy produced in these plants follows many stages before and after generation to reach our homes. However, flawless communication and transmission within the facilities are essential, which highlights the importance of the cables used.

In this article, we will discuss the cables used in thermal and geothermal power plants. These cables are of critical importance. Any possible communication interruption is highly undesirable and may put the SCADA system at risk. Additionally, fire-resistant cables prevent the spread and escalation of potential fires. For these and many other reasons, the cables used in such facilities are vital.

Before addressing the cables themselves, let us briefly explain thermal and geothermal power plants.

Thermal Power Plants Thermal power plants release chemical energy by burning coal and derivative fuels in specific systems. This energy is then converted into mechanical energy, and subsequently into electrical energy.

In broader terms, coal or lignite is burned in boilers at very high temperatures (800–900°C). The water inside the boiler’s pipe systems evaporates under the heat. The high-temperature, high-pressure steam is directed to turbines. The turbines rotate, driving the generator system to produce electricity.

The main equipment of a thermal power plant includes:

- Boiler

- Turbine–Generator

- Condenser

- Cooling Tower